Maple Sap Monitoring – A Case Study

In the maple industry, Smartrek vacuum sensors are installed in the woods at the end of sap collecting tubings to increase vacuum levels at taphole in order to effectively manage leaks and losses in the collecting system, and thus, reduces manpower, increases yield and profitability.

Maple syrup is a natural sweetener and a delicacy produced in northeastern North America. During springtime, Mother Nature’s freeze and thaw cycles push water through maple trees, producing a large amount of sweet sap that is collected and boiled down to obtain pure syrup. Harvesting was traditionally done using buckets hanging down a spout hammered into the tree. Nowadays, producers have replaced these buckets by a large network of tubing running through the sugar orchard. The maple sap is then vacuumed from the trees during the sugaring season.

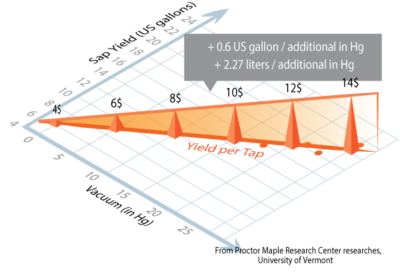

A team of researchers from Proctor Maple Research Center at the University of Vermont found out that sap yield was directly proportional to the level of vacuum that can be achieved at the taphole. Therefore, a maple harvesting tubing system has to be maintained and kept as leak free as possible. Most maple farms are pumping at extremely high vacuum levels, up to 28 in Hg. Unfortunately, at such a high vacuum, a small leak usually results in sap freezing in the surrounding tubing section which translates into a significant decrease in vacuum. Without any kind of measurement to indicate where the leaks are, maple farmers have no choice but to send dozen of workers into the woods to chase the leaks randomly for the entire season.

The Project

Maple operation & process monitoring

Smartrek Monitoring System has been installed in a maple bush in northern Maine. Miles of tubing run into the woods from tree to tree, each to be vacuumed by seven pumping stations scattered over 385 acres of unorganized land. In such a remote location, making a standard monitoring system cost-effective is hard to envision. First, there is no cellular network available, making it impossible to send vacuum data directly to the internet. Furthermore, the network size has to be rather large, by wireless mesh standards, with 85 end of lines under canopy to monitor on hilly terrain. That’s foliage and terrain blockage all in one.

The deployed monitoring system was thus a perfect match for that industry. With the extremely low power Spidermesh technology, sensors operated on 3x D-cell alkaline batteries, requiring no solar panel, could operate for years at a time. And the scalability of the network allowed all 85+ monitors to be connected to the same radio network without using any outside services (such as Wifi, internet, cellular). Moreover, standard services such as text messages could piggyback through the same mesh network for added-value.

Several parameters were monitored on-site, including telemetry for discharge pressure and tank levels. Pumping equipment were also connected to the system for remote controlling. 5 sniffers were also carried around by workers, which were intended for roaming inside the network to allow workers to target the leaks while in the field and to assess the effectiveness of the tubing repairs, as well as allowing monitoring of worker activities on a location basis throughout the day.

The Sensors

Sensors for the monitoring of the maple sap harvest and for equipment control/automation:

- Vacuum sensors

- Ultrasonic tank level sensors

- Remote controls

- Current sensors

- Pressure sensors

- Water counters

- Flow & Volume sensors

Other Equipment

Sensors and modules installed in other maple farms for the maple syrup process monitoring:

- Reverse Osmosis Control

- Refractometer

Sensors installed in the sugarbush are polled by the gateway at a medium acquisition speed.

Spidermesh benefits

The wireless mesh technology was proven to be very reliable in this very harsh environment, with high RF occlusion from both ground and vegetation. While typically, the link range between two sensors is as high as 10-kilometres in direct line of sight, this range was severely reduced to 500-meters in dense deciduous forest conditions. As a result, communication paths to the gateway are often indirect and can only be achieved by hopping from one sensor to another through multiple paths.

Redundancy of messages flooded into the network at periodic intervals ensured timely delivery of the data packet. This type of WSN (wireless sensors network) relies on the nodes themselves, extending the network which removes the necessity to install specialized high gain antennas. As a result, the installation and maintenance cost was significantly reduced.

Spidermesh cooperative mesh technology benefits:

- Battery operation on 3x D cell alkaline batteries with 5-years autonomy

- No solar panels

- No specialized high gain antennas

- One network connecting all sensors

- Real-time data acquisition

- Reliability in high RF occlusion settings

Network flooding increases communication reliability.

Results

Enhanced productivity was achieved using the real-time data acquisition system, which resulted from greater management efficiency (operational and labor) and from increased sap yield. Overall, the improved tightness of the tubing system was estimated to allow the producer to increase the vacuum level at the taphole by 1-2 in Hg. According to Proctor Maple Research Center, every added inch of mercury of vacuum will yield an additional 0.6 US gallon. As a consequence, the 30 000 taps sugarbush produced an additional 3 750 lbs of maple syrup, worth 10 350$.

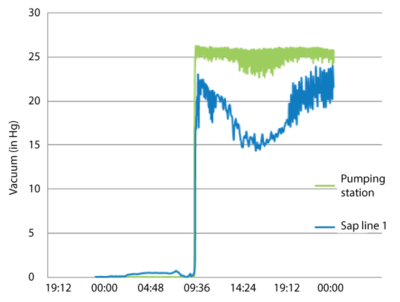

Furthermore, analysis of the recorded data allowed farmers to rethink their sap collection system. Undersized tubing at several places was found to be a major limitation in achieving high vacuum at the end of sap collecting lines. Mechanical extractors were also found to generate a fair amount of leaks themselves and were replaced for more efficient electrical extractors. As seen in the figure below, high vacuum buildup was not possible when the extractor is releasing sap from the vacuum chamber at a high rate.